Online Service

Online Service

Top

Top

Service

Service

Feedback

Feedback

You May Like

You May Like

Product details

Introduction

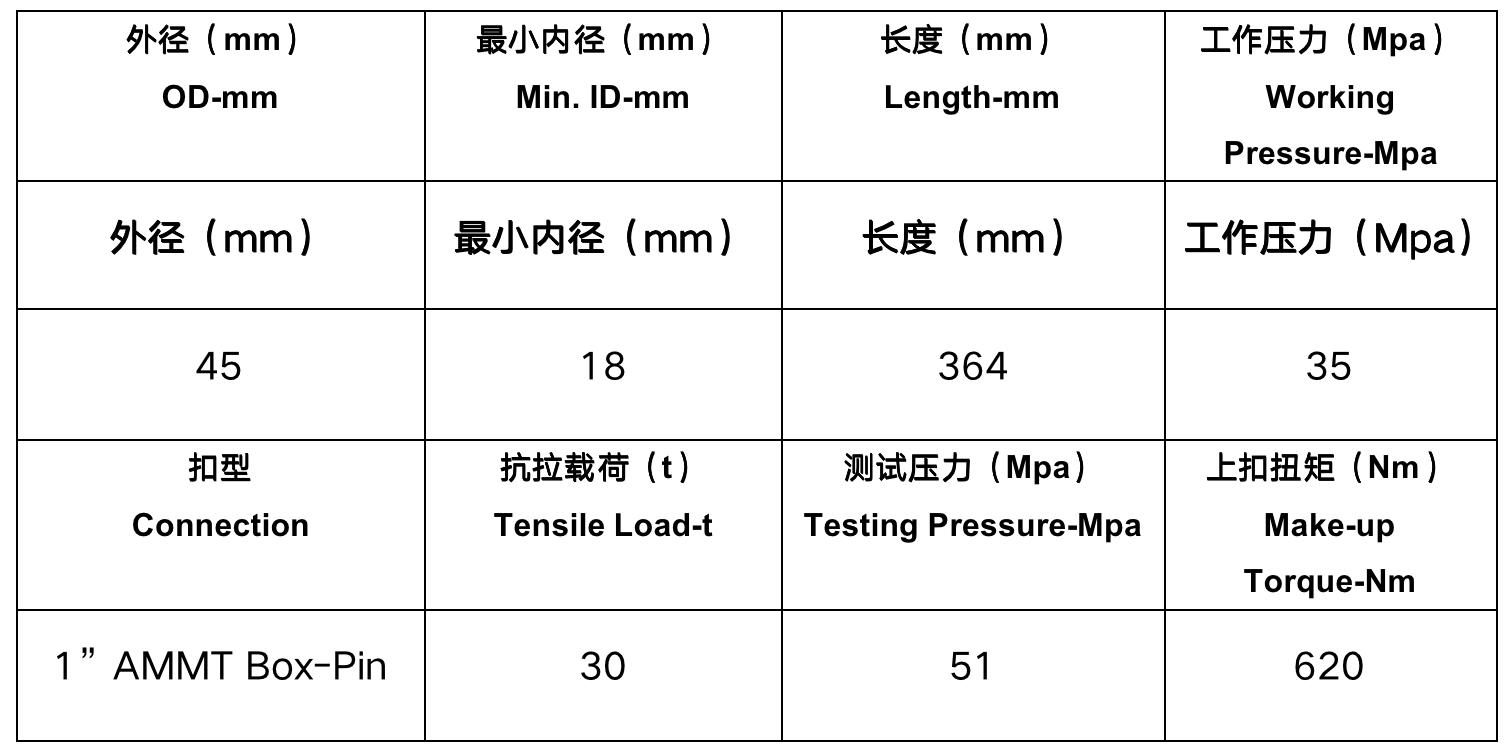

As a standard tool for coiled tubing operating BHA string, the double flapper check valve acts as a single flow direction, the dual flappers provides a pressure seal in one direction and the other for fluid flow. At low pressure, the flappers and seat seal ring contact seal, at high pressure, the flappers and seat metal seal which achieve effective pressure seal at low and high pressure.

Structure

Double flapper check valve contains two sets of flapper modules, each of which has function to hold back pressure.

In free condition, the flappers of the valve module will be in the closed position under the action of the reset spring, it can rotate around the pin shaft as long as pumping. After the rotation of flappers, a larger channel can be obtained to allow a ball-drop operation.

Characteristics

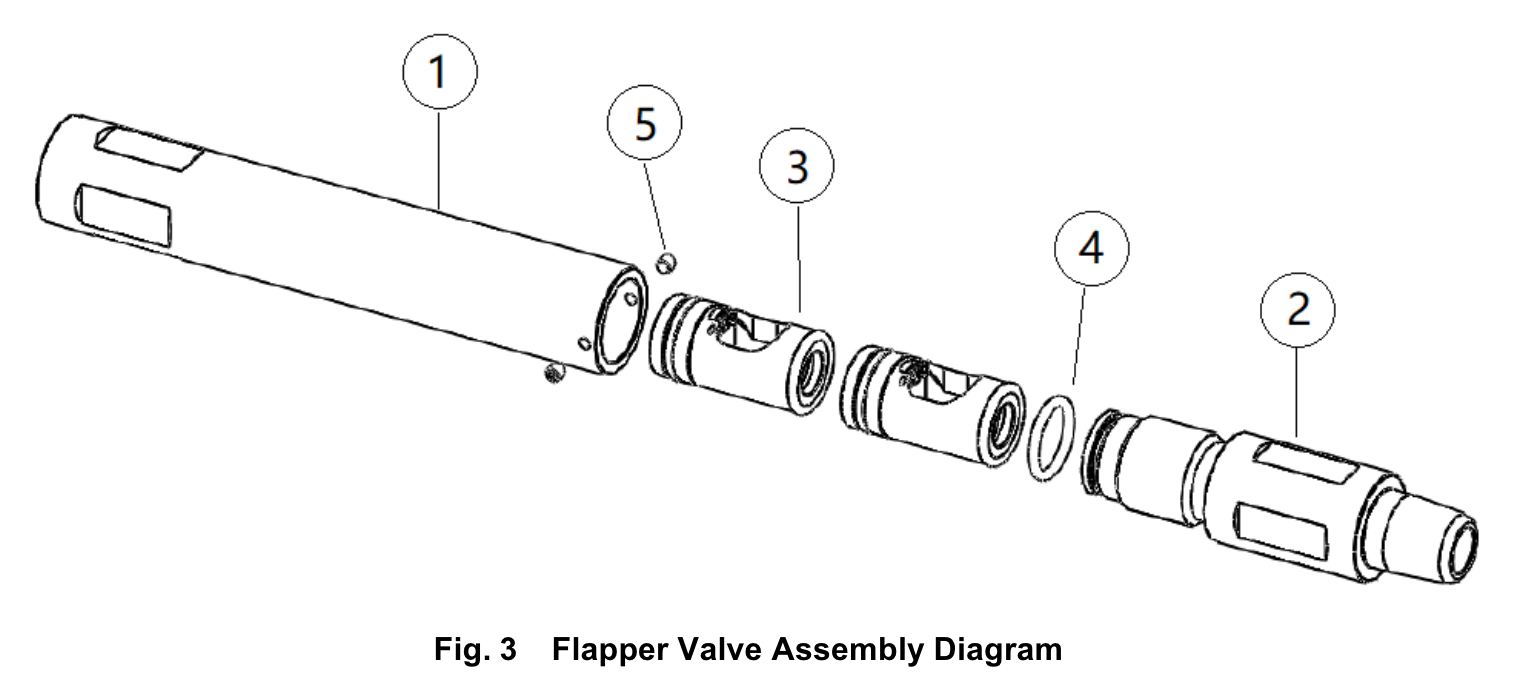

Specification

iagram

Assembly Procedure

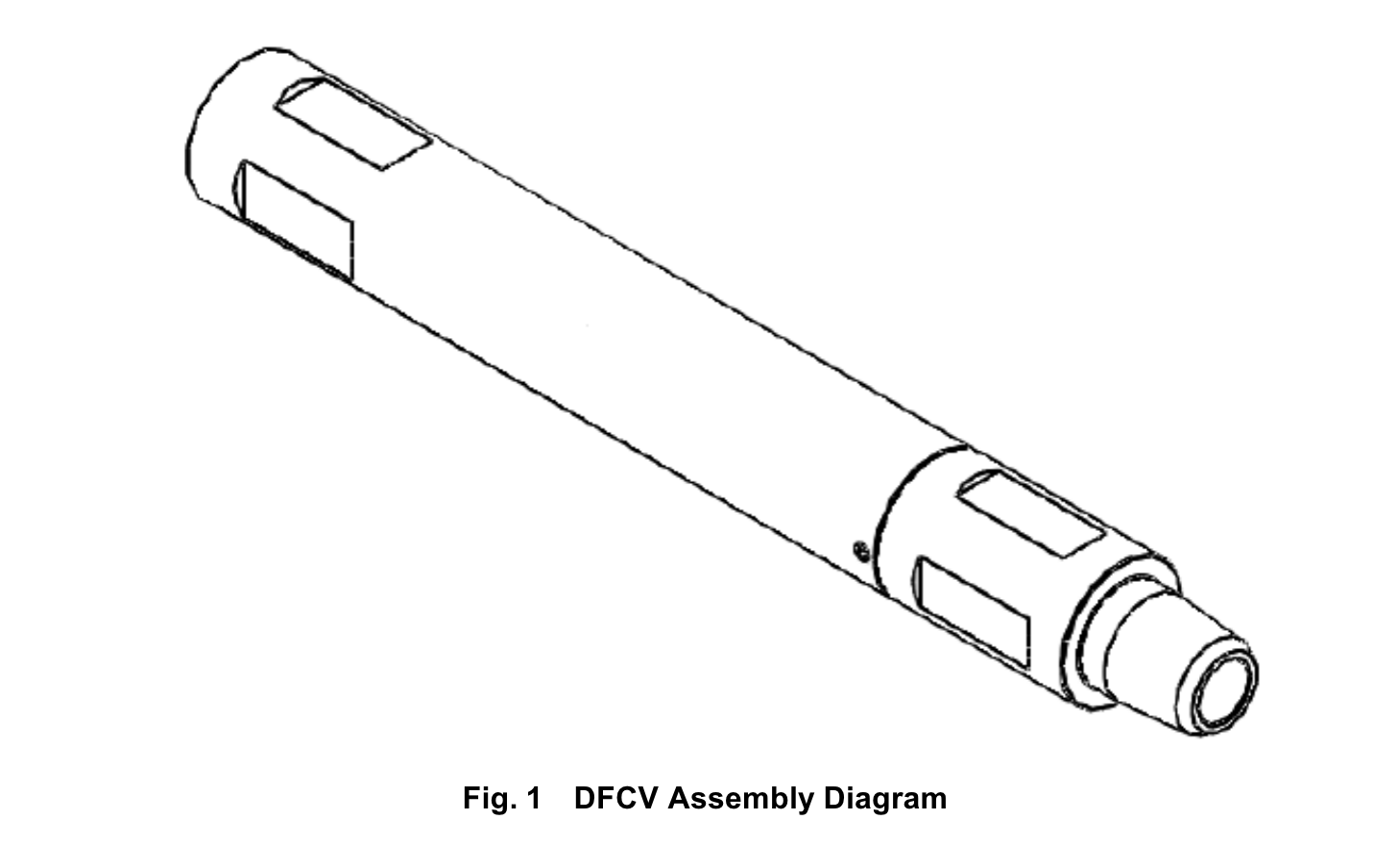

1、Install flapper(3), reset spring(7) to valve pocket(2).

2、Insert pin(6) through valve pocket(2), flapper and reset spring to a module, then visually check length of pin(6), cut or mill if the pin is too long.

3、 Install flapper seal(5) and O-ring(4) to valve seat(1), then grease the O-ring(4).

4、Install valve seat(1) on to the bottom of valve pocket.

5、Place O-ring(8) to other side of valve pocket, then grease the O-ring. Refer to fig.2.

Flapper Valve Assembly

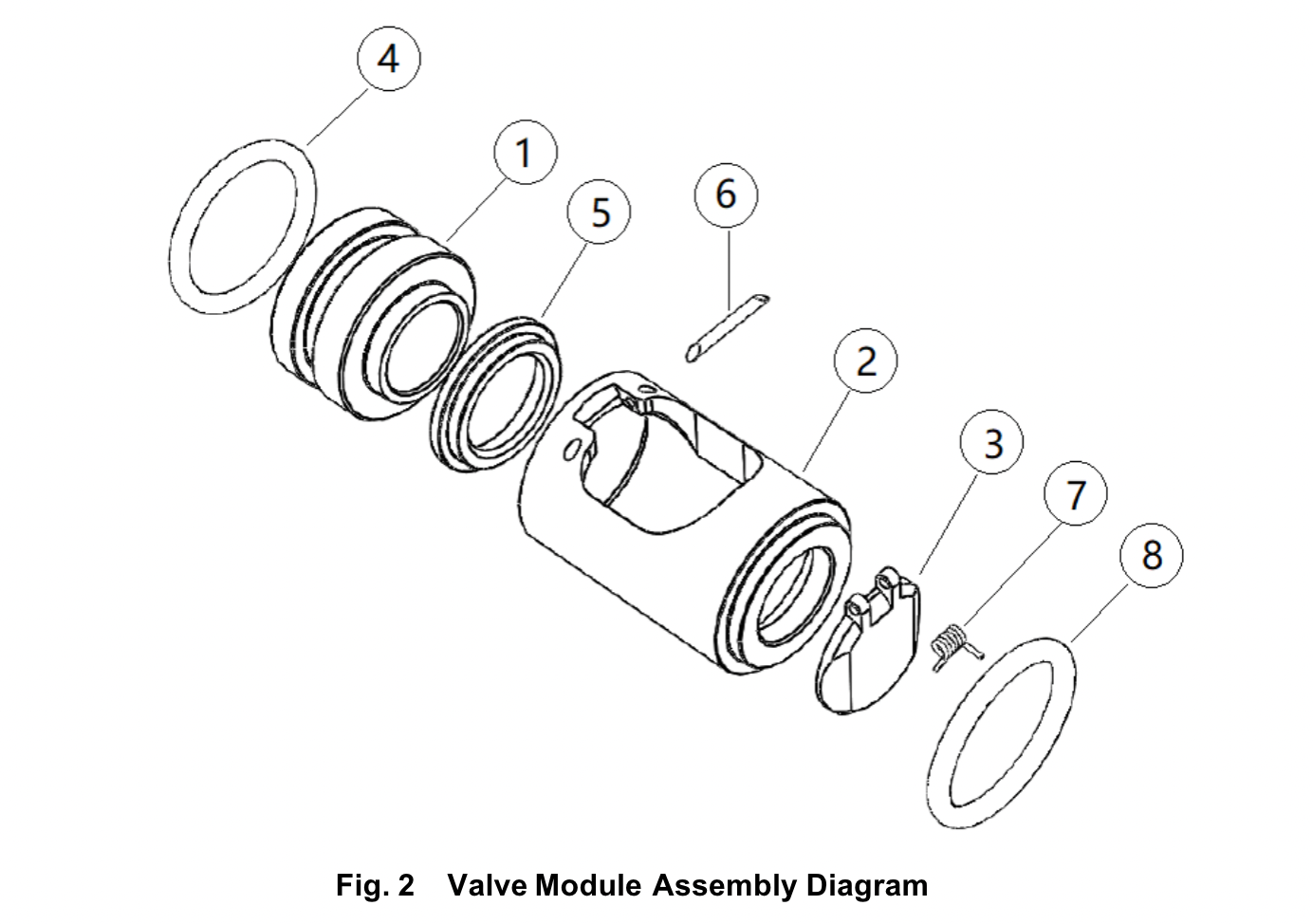

1、Insert the two flapper modules(3) in to upper connector(1).

Note: ensure install direction of flapper module.

2、Install O-ring(4) to seal groove of lower connector(2), then grease the O-ring. Make up lower connector(2) with upper connector(1), then tighten up properly. Refer to fig.3.

End of Installation.

Operation Notices

1、Prior to work, confirm parts or components specification and used conditions.

Note: DFCV shall be selected separately for common and CO2, H2S operation condition.

2、Prior to work, visually check the connection thread on both sides and ensure there are not damage.

3、Prior to work, ensure the DFCV is functionally in good working condition.

4、While connecting tools, ensure enough make-up torque applied.

Note: To make up 1” AMMT thread, it is recommended to apply thread fastener then tighten up to required torque.

5、Perform tool maintenance or repair after each operation/job.

Maintenance Notices

1、No allow to use improper hand tools to knock on tools body by using steel bar for tool disassembly and assembly, could use the brass bar,aluminium bar and wooden bar.

2、Replace the visible broken parts to maintain tools function.

3、If there is no visible damage, suggest to do tool scanning inspection to ensure no cracks and etc. inside.

4、To replace sealing parts could be depending on actual conditions.

Note: validation duration of sealing parts after manufacturing is18 months

5、To store tools, shall be prevented from strong sunshine and high temperature, better in cool and ventilated space.

6、To transport tools, put thread protectors on both sides of tool.

Global Hotline

+86 18123856630

If you have any questions, please contact the customer service email: service@atoilgas.com

Service Time:

Monday to Friday, 10:00 to 17:00 Beijing Time

Scan and follow us

Scan and follow us